Patented system for handling waste electronic and electric equipment

Patented system for handling waste electronic and electric equipment – WEEE

The magnets

The Magnojack and Magnoclamp system is an innovative solution for handling Waste Electrical and Electronic Equipment (WEEE). Using permanent magnets, these tools securely grip and move large appliances, addressing manual handling challenges in WEEE recycling. Magnojack is a magnetized sack truck for manual movement, while Magnoclamp is a forklift attachment for mechanical lifting and stacking. Designed to handle loads up to 120 kg, this magnet-based concept improves safety, efficiency, and environmental compliance across the WEEE handling process, from collection points to recycling facilities

The magnets

The Magnojack and Magnoclamp system is an innovative solution for handling Waste Electrical and Electronic Equipment (WEEE). Using permanent magnets, these tools securely grip and move large appliances, addressing manual handling challenges in WEEE recycling. Magnojack is a magnetized sack truck for manual movement, while Magnoclamp is a forklift attachment for mechanical lifting and stacking. Designed to handle loads up to 120 kg, this magnet-based concept improves safety, efficiency, and environmental compliance across the WEEE handling process, from collection points to recycling facilities

Handling without the product

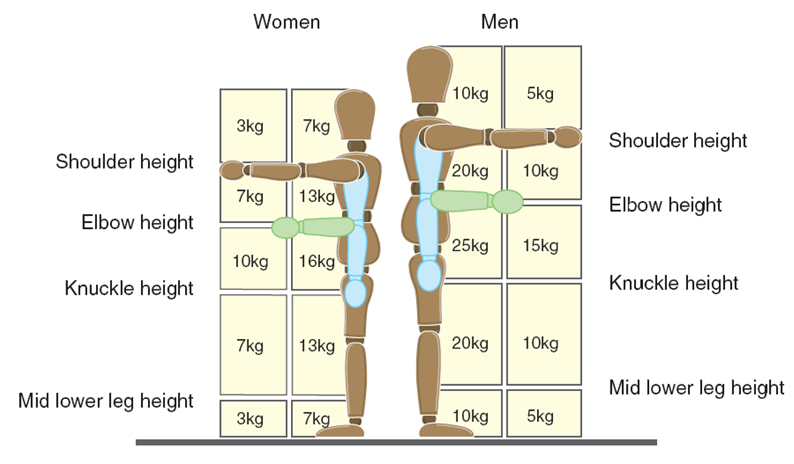

Large WEEE items are often handled manually or with unsuitable equipment like standard sack trucks. This is inefficient and poses significant safety risks to employees. Manual handling increases the risk of personal injuries and repetitive strain injuries, especially when moving heavy appliances like washing machines or cookers. Traditional solutions often require two-person operation, are slower, and may damage the products.

Handling without the product

Large WEEE items are often handled manually or with unsuitable equipment like standard sack trucks. This is inefficient and poses significant safety risks to employees. Manual handling increases the risk of personal injuries and repetitive strain injuries, especially when moving heavy appliances like washing machines or cookers. Traditional solutions often require two-person operation, are slower, and may damage the products.

Environment

This system contributes to more efficient and environmentally friendly handling of WEEE. By enabling safe and efficient handling of appliances, these systems support the EU’s goals for increased WEEE recycling. They prevent damage to refrigerator and freezer elements, reducing the risk of CFC gas emissions. The systems optimize the loading process, which can reduce the number of transports and thereby decrease CO2 emissions. They also support the proper upright storage of cooling furniture containing CFCs, HCFCs, or HFCs, which are classified as Hazardous Waste.

Environment

This system contributes to more efficient and environmentally friendly handling of WEEE. By enabling safe and efficient handling of appliances, these systems support the EU’s goals for increased WEEE recycling. They prevent damage to refrigerator and freezer elements, reducing the risk of CFC gas emissions. The systems optimize the loading process, which can reduce the number of transports and thereby decrease CO2 emissions. They also support the proper upright storage of cooling furniture containing CFCs, HCFCs, or HFCs, which are classified as Hazardous Waste.

The system

The Magnojack and Magnoclamp system utilizes powerful permanent magnets to securely hold and move appliances during handling

The system

The Magnojack and Magnoclamp system utilizes powerful permanent magnets to securely hold and move appliances during handling

The Magnet Family

Reduced traffic

Fewer trips contribute to decreased road congestion, particularly in urban areas where many collection points are located.

Prevent damage

Prevents damage to refrigerator and freezer elements, reducing the risk of CFC gas emissions.

Optimized stacking

The system allows for ‘4×3’ stacking – four appliances across and three high in trucks and containers. This maximizes available space utilization.

Reduced traffic

Fewer trips contribute to decreased road congestion, particularly in urban areas where many collection points are located.

Prevent damage

Prevents damage to refrigerator and freezer elements, reducing the risk of CFC gas emissions.

Optimized stacking

The system allows for ‘4×3’ stacking – four appliances across and three high in trucks and containers. This maximizes available space utilization.

Technical information

Technical information

Dealers

Donovan Nordic AS

Olav Lauvdal

Fidjestøl,4534 Marnardal

Tel: +47 416 39 416

Mail: ol@magnojack.com

Waizinger Ges.mbH & Co KG

Ennser Str 119

4407 Dietach, Austria

Tel: 07252 / 381 91 0

Mail: office@waizinger.at

Dealers

Donovan Nordic AS

Olav Lauvdal

Fidjestøl,4534 Marnardal

Tel: +47 416 39 416

Mail: ol@magnojack.com

Waizinger Ges.mbH & Co KG

Ennser Str 119

4407 Dietach, Austria

Tel: 07252 / 381 91 0

Mail: office@waizinger.at

Gillard Constructeur

Bruno Gillard

ZA Rue des Peupliers

77590 – Bois le Roi, France

Tel: 0033 (0)1 60 69 68 66

Mail: Bruno.gillard@gillard-sas.fr

German EcoTec GmbH

Dr. Alexander Rochlitz

Neuenkampsweg 4

25337 Elmshorn, Germany

Tel: +49 4121 5789890

Mail: info@german-ecotec.com

UK

We are currently searching for dealers in the UK.

Gillard Constructeur

Bruno Gillard

ZA Rue des Peupliers

77590 – Bois le Roi, France

Tel: 0033 (0)1 60 69 68 66

Mail: Bruno.gillard@gillard-sas.fr

German EcoTec GmbH

Dr. Alexander Rochlitz

Neuenkampsweg 4

25337 Elmshorn, Germany

Tel: +49 4121 5789890

Mail: info@german-ecotec.com

UK

We are currently searching for dealers in the UK.